- Ten years ago, MIT students and faculty came up with an alternative design for an emergency ventilator, using the Ambu resuscitation bags that are commonly found in hospitals.

- Now, a new team of MIT researchers has revived the effort to make the designs available for free online.

- Armed with the cheap designs, which only require about $500 in parts to produce, non-traditional manufacturers, like auto companies, could ramp up production of ventilators.

Considering there are only about 160,000 ventilators in U.S. hospitals, and there are already over 144,000 cases of COVID-19 (coronavirus) as of press time, the country will soon feel the shortage of these life-saving devices as doctors make decisions about who gets a breathing machine and who doesn't. The Centers for Disease Control and Prevention (CDC) expects the U.S. to have a ventilator shortage on the order of 300,000 to 700,000 units.

As some unorthodox potential ventilator manufacturers have crawled through the cracks to pad out the shortage—from Elon Musk's companies Tesla and SpaceX, to U.K.-based vacuum-maker Dyson, to General Motors and Ford—questions loom about their ability to put out the complex medical devices in a reasonable amount of time. How will these firms pivot their production facilities to ventilators, and what designs will they use?

Now, volunteer engineers, physicians, and computer scientists at the Massachusetts Institute of Technology have a potential solution that should only cost about $400 to $500 in parts to produce. MIT plans to make these designs available online for free to help companies around the world shift to ventilator production.

These researchers formed MIT E-Vent, as the team is known, less than three weeks ago in response to doctors' urgings to revive a decade-old MIT project in medical device design. In 2010, students and faculty working with physicians local to the Cambridge, Massachusetts area came up with designs for a simple ventilator machine. They published a paper in the Journal of Medical Devices outlining that work, but it never went any further.

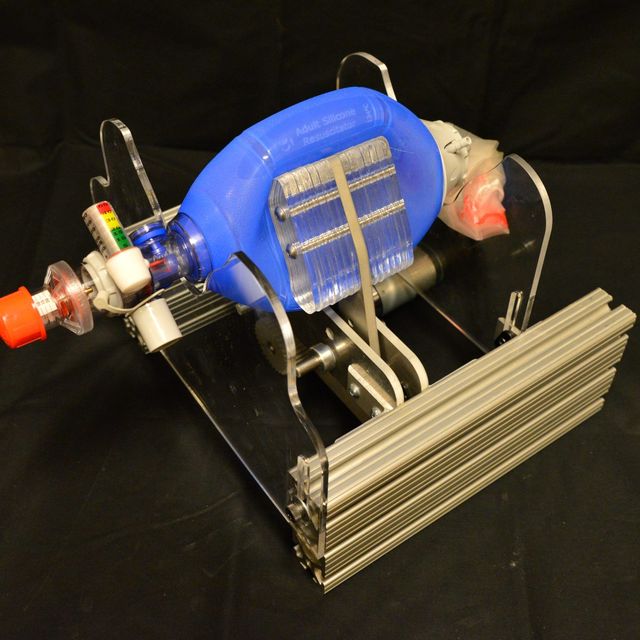

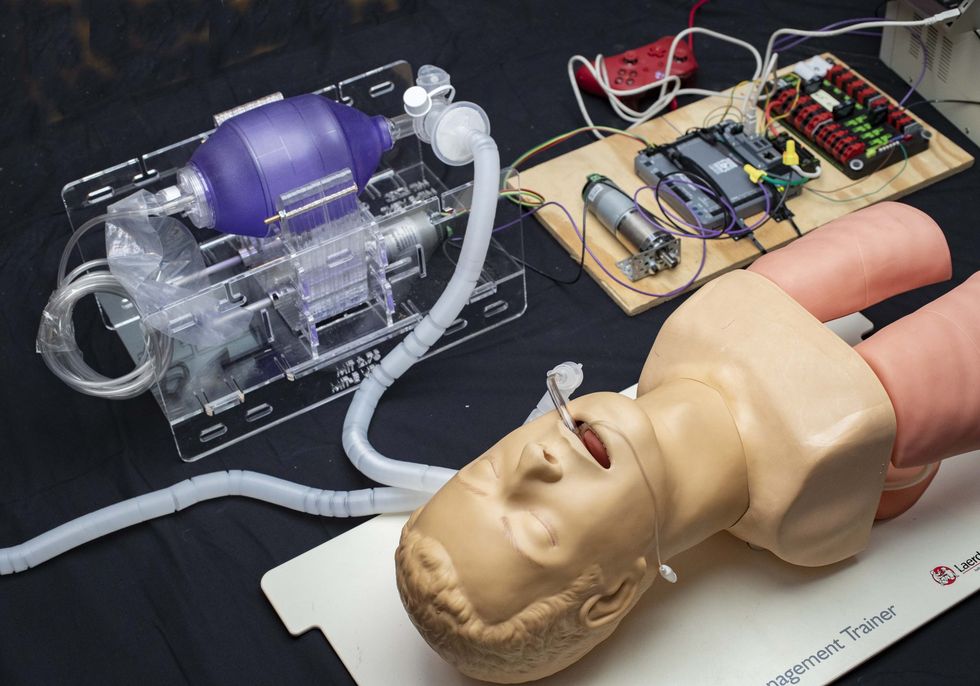

Now, the new team is rapidly expanding that work to create a real-life ventilator solution. The design makes use of an unlikely hero: the Ambu resuscitation bags commonly found in hospitals. Emergency technicians or medical professionals hand-operate these bags to create airflow to the lungs until a ventilator becomes available. A tube is inserted into the person's throat, while the trained professional squeezes and releases the flexible pouch.

MIT is adapting the Ambu bags by creating a mechanism that can automate the squeezing and releasing motions, since it isn't practical to expect someone to sit around and pump these bags for days on end. In case of any mechanical failures, the MIT design makes it possible to convert the Ambu bag back to a hand-operated device if need be.

"Any solution should be utilized only in a healthcare setting with direct monitoring by a clinical professional," the researchers are careful to note on the MIT E-Vent website. "While it cannot replace an FDA-approved ICU ventilator, in terms of functionality, flexibility, and clinical efficacy, the MIT E-Vent is anticipated to have utility in helping free up existing supply or in life-or-death situations when there is no other option."

It isn't yet clear when the team will wrap up prototyping efforts, but the scientists do want to eventually secure U.S. Food and Drug Administration (FDA) approvals, according to MIT. Notably, FDA barriers have been lowered to spur production in the time of the COVID-19 pandemic.

Right now, the team is operating without funding, and team members are staying anonymous to keep from getting swamped with inquiries. That's where the MIT E-Vent website becomes so valuable. It has enough updated information for outside teams to work in parallel with the MIT team, the researchers told the university's press office.

You can make a tax-deductible donation to the research team here.